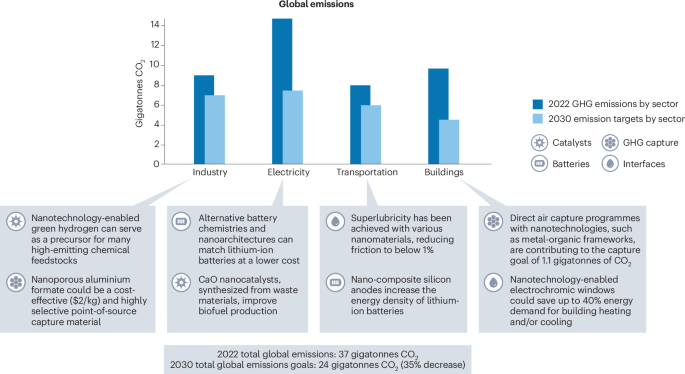

Reaching net-zero emissions by 2050, as well as substantial near-term emission reductions by 2030, are needed to avoid the worst impacts of climate change globally. There is a unique opportunity for nanotechnology to contribute to this goal (Fig. 2) by focusing on high-emission sectors such as buildings, electricity, industry, and transportation. Urgent action is needed to rapidly scale-up and implement new climate solutions, drawing insights from successful nanotechnology applications.

High-emission sectors, industry, electricity, transportation, and building are high-opportunity areas for nanotechnology-enabled innovations to make a step-change impact to meet global climate goals. For more information on 2022 global emissions and 2030 targets please refer to ref. 25.

Globally, buildings account for almost 9.8 gigatonnes of CO2 released into the environment each year. According to the IEA, overall building-related emissions, which are mainly from heating and cooling, must decrease to 4.4 gigatonnes CO2 yr–1 to reach net-zero globally2. Chromic nanocoatings (for example, thermochromic, electrochromic, and photochromic) can change a window’s optical properties based on external stimuli and thereby decrease solar thermal impact and hence the need for cooling. Electrochromic windows alone have the potential to save up to 40% of energy demand for building heating and/or cooling23.

Decarbonization of the electricity sector will heavily depend on advances in batteries and energy storage to tie intermittent renewable energy to the grid. According to the IEA, the electricity sector will need to abate 7 gigatonnes of CO2 yr–1 globally by 20302. Nanotechnologies are already helping achieve higher energy and power densities in traditional Li-ion batteries and new approaches are being added to the market. Nanotechnology-enabled iron–air batteries for grid storage are currently under commercial development, with claims that they can achieve 100 hours storage, at one tenth of the cost of traditional lithium-ion batteries (https://formenergy.com/technology/battery-technology/). Improved nanoarchitectures could also allow for other emerging battery chemistries with optimized characteristics to match Li-ion batteries at a lower cost24; but access to advanced processing and manufacturing techniques currently represent a bottleneck to accelerate the scaling-up of these solutions24. Researchers and entrepreneurs in the United States have voiced the need for a Manufacturing USA institute focused on advanced battery manufacturing to help reduce cost and risk of new materials and manufacturing techniques.

The industrial sector — made up of aluminium, cement, chemicals, light industry (for example, food processing, textiles, and consumer goods), paper, and steel — needs to reduce emissions by 2 gigatonnes of CO2 yr–1 globally by 20302. Here, nanocatalysts have an enormous role to play. A promising approach is the development of green hydrogen; but the process is currently two to three times more expensive than producing hydrogen from natural gas. Cheap and abundant green hydrogen can serve as a precursor for many high-emitting chemical feedstocks, such as ammonia, methanol, ethylene, propylene, benzene, toluene, and xylenes, which account for around 75% of GHG emissions in the chemical industry globally. Several companies are working on novel ways to produce and utilize green hydrogen. For example, a company developed heterogeneous nanocatalysts to produce green hydrogen (https://www.aircompany.com/technology/) that is then used to transform captured CO2 from industrial plants into value-added chemicals using a nanocatalyst. Optimized electrolysers, Earth-abundant nanocatalysts, and improving nanocatalysts’ lifetime and reliability could decrease costs and scale-up circular economy solutions. To date, there are 40 GHG capture and utilization commercial facilities accounting for a modest 0.05 gigatonnes CO2 captured annually worldwide2. Increased commercial and government support has propelled over 500 new pilot plants, demonstration projects, and commercial plants in various stages of development2.

The transportation sector currently emits nearly 8 gigatonnes CO2 yr–1 globally. By 2030, a reduction of almost 2 gigatonnes CO2 yr–1 globally is targeted through enhanced efficiency and technology adoption. Multiwall carbon nanotube additives and carbon coatings on silicon particles in Li-ion battery electrodes are already being used in commercial electric vehicle batteries24. One company, whose batteries are being deployed by a major automobile company, claims that its nano-composite silicon anode lithium-ion batteries can currently achieve 20% more energy density than traditional Li-ion batteries (https://www.silanano.com/our-solutions/titan-silicon-anode) while diminishing the use of critical materials. Nanotechnology could also hold the key for mobile energy delivery beyond batteries, including hydrogen-storage and fuel cell solutions.

Across a variety of critical technology sectors, nanoengineering can enable the kind of performance leaps needed to mitigate climate change. However, the severity and urgency of the issue demands that we consider not just technical potential, but also the economic, manufacturing, workforce, and adoption hurdles that could impede the realization of nanotechnology’s potential before irreversible harm is done. Given the urgency, it is important to prioritize drop-in technologies that can be incorporated into existing infrastructure and supply chains, and to use Earth-abundant materials to remove barriers for adoption. There are many federal resources available in the United States (for example, I-Corps, Small Business Innovation Research grants, ARPA-E SCALEUP) to help scientists advance the technology readiness level of their inventions. Federally funded user facilities (https://www.nano.gov/userfacilities) can also serve as a resource for business and researchers to characterize and further develop their climate solutions. Public–private facilities, such as Manufacturing USA, can provide advanced manufacturing capabilities for climate solutions, but need to be expanded to streamline production. Artificial intelligence (AI) tools are being developed to help move low technology readiness innovations toward commercial deployment. Nanotechnology-enabled step changes in semiconductors are powering the AI revolution, which can help accelerate climate change solutions by rapidly marrying capabilities with technical demands. AI-enabled nanomaterials design may eventually enable long sought-after technologies such as high-temperature superconductors, a virtuous cycle enabling yet another step-change in computational energy efficiency.

Nanomaterials’ size-dependent properties and the ability to tailor materials to desired physicochemical properties can drive, and already are driving, technical solutions in the realms of energy storage, catalysis, interfaces, and GHG capture. These are environmentally and economically valuable opportunities, many of which have shown real climate impact and economic viability. For its part, Nano4EARTH is mobilizing the entire nanotechnology community: researchers, entrepreneurs, government, industry, investors, and philanthropists to combat climate change on all fronts.